We manufacture fabric ducting and diffusers of all dimensions from 100 mm to 2000 mm, each designed to specific requirements. The fabric duct inlets and connection spigots are always manufactured 10-15 mm larger than the specified size/diameter for ease of connection.

Tailor-made fabric ducting solutions

Fabric ducting & diffusers can be of various shapes, dimensions, lengths, airflow distribution methods or suspension types. We make our fabric ducts from various fabric types of different colors. We offer fabric duct solutions for every situation that always correspond to demanding customer requirements.

Cross section of fabric ducting

Positive pressure only

C – CIRCULAR

The standard shape of fabric duct, easy maintenance, preferentially recommended.H – HALF-ROUND

For use where there is not enough space for circular fabric duct and for aesthetic fabric duct applications.Q – QUARTER-ROUND

For use where there is not enough space for circular fabric duct, in aesthetic applications and if the fabric duct is to be installed in the corner of a room.SG - SEGMENT

For use where there is not enough height fora half-round fabric duct.

SC - SECTOR

Available if the room corner construction requires a different shape of fabric duct to quarter round.OVER PRESSURE AND NEGATIVE PRESSURE

S – SQUARE

This shape of fabric duct requires a special suspension structure (provided) to clamp and support all corners.Sizes and Diameters

Length

Determining the length of fabric ducting & diffusers depends primarily on the availability of space. We can manufacture a fabric ducting to deliver the same air volume whether the fabric duct is short or long, the precise design depends on the material type, perforation designs and system pressure.

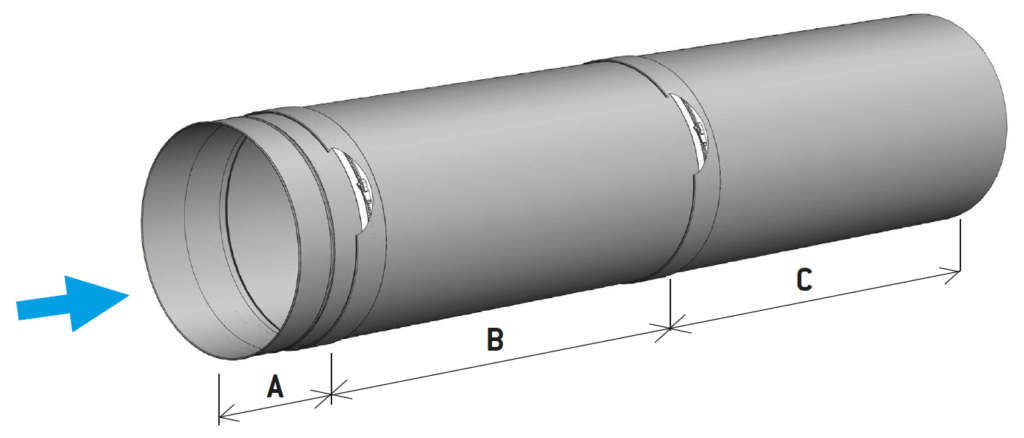

A – beginning (edge /zip) – length 100mm – 200 mm

B – continuous part (zip/zip) – length 5000mm –10000 mm, these are multiplied to create the correct fabric duct length

C – blind part (zip/end) – length from 100mm to 11000 mm

Individual fabric duct parts are connecting with zippers; the number of zippers (or the distance between them) is flexible and can be specified by the customer.

Pressure

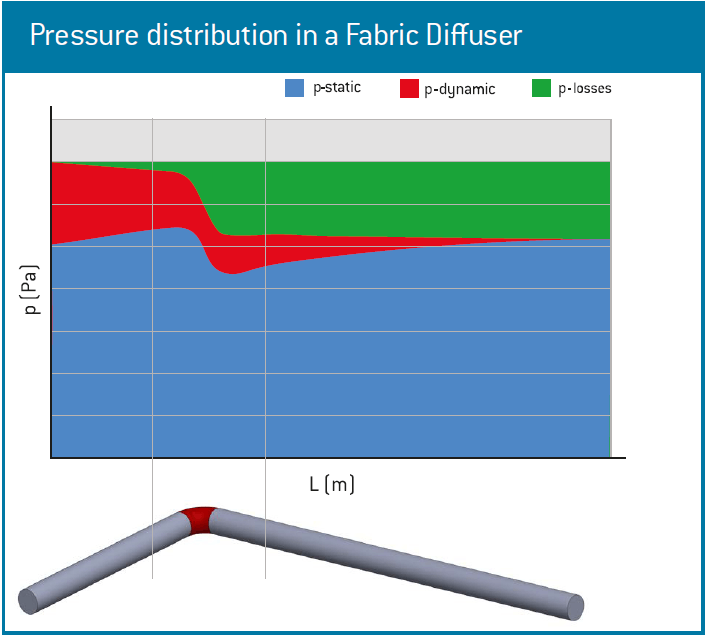

Pressure losses of fabric ducting & diffusers are very similar to those in the traditional ducting. Calculating a more complex fabric duct distribution system is achieved using similar methods to those for sheet metal ducting. The minimum static pressure necessary to keep the correct shape of a fabric ducting or diffuser depends upon the weight of the fabric used. A minimum of 20 Pa is sufficient for light materials and 50 Pa necessary for medium and heavy ones.

The pressure distribution along fabric ducting is different from traditional sheet metal ducting because with declining airflow longitudinal velocity decreases. To verify the design of your fabric duct distribution system, please contact us.

Let us prepare a tailor-made fabric ducting solution for you!