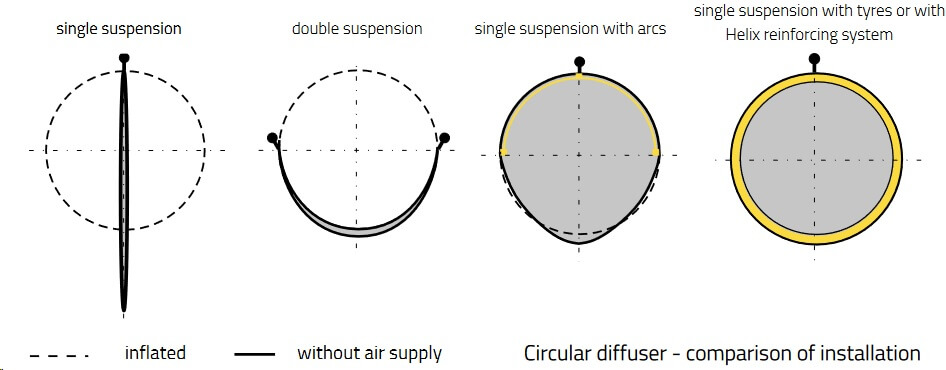

1. What does a Fabric Duct look like when the fan is switched off?

2. Is it possible to use Fabric Ducting for extract (exhaust air)?

PŘÍHODA s.r.o. were the first manufacturer worldwide to introduce negative pressure ducting onto the market. The

principle consists in sufficiently tensioning all ducting walls using tensioners in the case of a square cross-section or

inserting the Helix reinforcement and the tensioner in the blind in the case of a circular one. The construction enables

simple disassembly and re-installation. Laser cut perforations are used to allow the air into the duct.

3. What is the service-life duration of Prihoda Fabric Ducts?

This is not a short term solution. Diffusers made from good quality fabrics will last for fifteen years or longer. Light

fabrics (PLS, NLS, approx. 100 g/m2) with maximum permitted number of 50 washing procedure or the cheap, (usually

polyethylene Foils (NLF) susceptible to tearing) may have limited durability.

4. What is the pressure loss of a Fabric Duct?

In a well designed straight diffuser there is an almost constant static pressure throughout. The fabric perforation is

calculated based on the average value of the static pressure. In other words, the diffuser is designed based on the external

static pressure of the system. Shaped pieces (bends) and turbulence equalisers present certain pressure loss which needs

to be taken into consideration. Loss caused by friction is usually minimal due to the decreasing air speed inside the diffuser.

The minimum utilisable pressure is 50 Pa, however Light material (PLS, NLS ) will inflate from 20 Pa.

5. Is it possible to use square or rectangular diffusers?

PŘÍHODA s.r.o. has developed a special construction which enables use of a quadrangular cross-section. The principal is

based on stretching the fabric in transverse and longitudinal direction by means of a tensioning system. The construction

enables simple disassembly and re-installation. Fabric ducting with quadrangular cross-section can be assembled directly

on the ceiling or suspended in the area.

6. What do you do with diffusers when they get clogged by dust or other contamination?

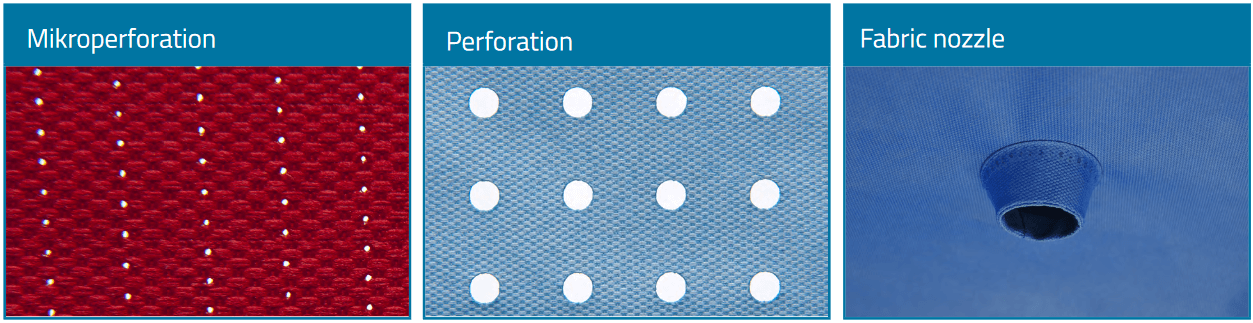

All of our products are easy to clean. Most of our fabric allow washing in a washing machine. Diffusers with perforations

(holes larger than 4mm) will never get completely clogged by contamination. Our diffusers with Micro-perforations have

considerably longer (more than double) period of operation between maintenance cycles than permeable fabric. usually

cleaning is only necessary due to hygiene or aesthetic reasons. Each part of our system separated by zippers has a unique

washing label which identifies its position and any washing instructions.

7. Can Fabric Ducts get mouldy?

Mould can form on any kind of material if it is moist and unventilated. This goes also for most of our fabrics, including those

with antibacterial finishing. Only one our fabric – Prihoda Plastic (NMF) – is mildew resistant. Never store moist diffusers

and do not keep them out of operation for long periods of time, especially in moist atmosphere. Mould can cause indelible

marks on the fabric.

8. Does the Fabric Duct function as a filter at the same time?

If permeable materials (PMS, PMSre, PMI, PLS) are used, the fabric functions as a filter for the part of the transferred

air that goes through the fabric. As the fabric contamination gradually increases, the pressure loss grows and the air

flow decreases. Therefore, it is necessary to wash the fabric. We consider the utilisation of microperforated or laser cut

perforated fabric to be by far the best solution. Although perforated fabrics do not function as filters they do not change

the pressure loss value and the number of necessary washing procedures significantly drops. We are a manufacturer of

distribution (not filtering) ducts and diffusers.

9. Why doesn’t PRIHODA use plastic nozzles or slots?

Use of plastic nozzles or longitudinal slots were a historical necessity. These tools used to enable certain air distribution

patterns, the nozzles in addition protected the frayed edges of the holes. When we began to use laser technology that

allows cutting of accurate holes with sealed margins, they became redundent. Correctly designed rows of laser cut holes

fulfil the same purpose, whilst being cheaper and more aesthetic. We use fabric nozzles for longest air flow and vertical

outlet of air , never plastic nozzles. Our fabric nozzles are light weight and sonic welded to the material they will not fall out

of the duct or damage the duct through friction during washing.

10. Why doesn’t PRIHODA use more permeable fabrics?

We use permeable materials to avoid condensation where supply air temperature is below dew point. However, we only

have material of a single permeability value. It is very low and serves just to prevent condensation. Distribution of air

is done exclusively using holes (perforation or microperforation or a combination of both) and adjusted holes (nozzles,

pockets). Our product portfolio also includes non permeable materials, which are often useful in other situations.

11. Which certificates do Prihoda fabric diffusers have?

Our materials are certified with respect to fire resistance as per EN 13501-1 and EN 45545 (in various classes, based on

the material) and as per the American UL. PŘÍHODA has a certified quality management system according to ISO 9001, an

environmental management system according to ISO 14001, an OHS management system according to ISO 45001 and an

EPD environmental impact certificate. Příhoda textile diffusers have also received the Oeko-Tex certificate.

Oeko-Tex ISO 9001 ISO 14001 ISO 45001

Any other question?